All of our springs are constructed from Certified Chrome Silicon wirestock to ISO 9001:2008 quality standards to withstand extreme heat and highly cyclic rate. The certification rating ensures a consistency in the parent material of 95%, which translates to repeatable consistency in performance & function. Certified Valve Quality Chrome Silicon wire is used in very high stress applications such as, NASCAR, Formula One, Moto GP & Pro Stock racing motor valve springs. It is not uncommon in some of these applications for valve springs to see 15,000,000 compression cycles in one race. It is this extraordinary capability that makes Chrome Silicon wire the obvious choice in our spring production vs. music wire or 17-7 PH used in OEM springs and by most aftermarket competitors. In addition, all of our Chrome Silicon buffer springs are heat treated, stress relieved, and dual-stage shot peened in separate post winding treatments. We also treat each spring with a proprietary, deep-penetrating, Re-Micronized (to .3 Micron particle size), inhibited, Molybdenum-Disulfide (MoS2) formulation to eliminate 90% of all mechanical wear on the spring. The combination of materials & processes result in a loss of no more than 5% in spring efficiency. The minimum anticipated duty cycles of our buffer spring designs are in excess of 1,500,000 cycles.

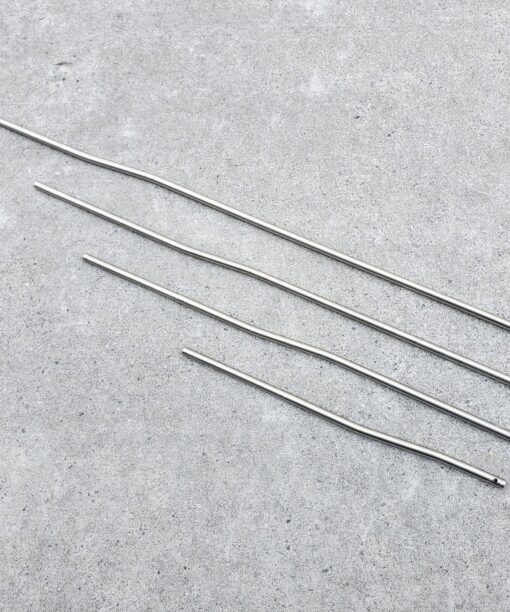

We take our extractor springs one step further with the addition of Cryogenic Processing. This computerized, ultra low temperature process (-320°F) increases the strength & wear life of the parent material through a change in microstructure resulting in less retained austenite and more uniformity in grain structure.

Why cryogenics for the extractor spring and not our other springs? Due to the size of the extractor spring, high stress cyclic rates and asymmetrical temperature exposure, premature wear and or shortened spring life can occur. Cryogenics effectively combats these issues giving the spring a very predictable & uniform performance within the operation of the weapon cycle.

While we really don’t know how long our extractor springs will last, round counts in excess of 200,000 ROUNDS (ongoing) are documented on a single extractor spring. We have 5-Coil Extra Power, 4-Coil Enhanced Power, and Extra Power .308 Dual Spring Sets in our comprehensive extractor spring lineup below. Neither our extractor springs, nor any other commercially available extractor springs are shot peened due to the unfeasible cost of manual labor and wire fixturing of such tiny springs in a complex process.

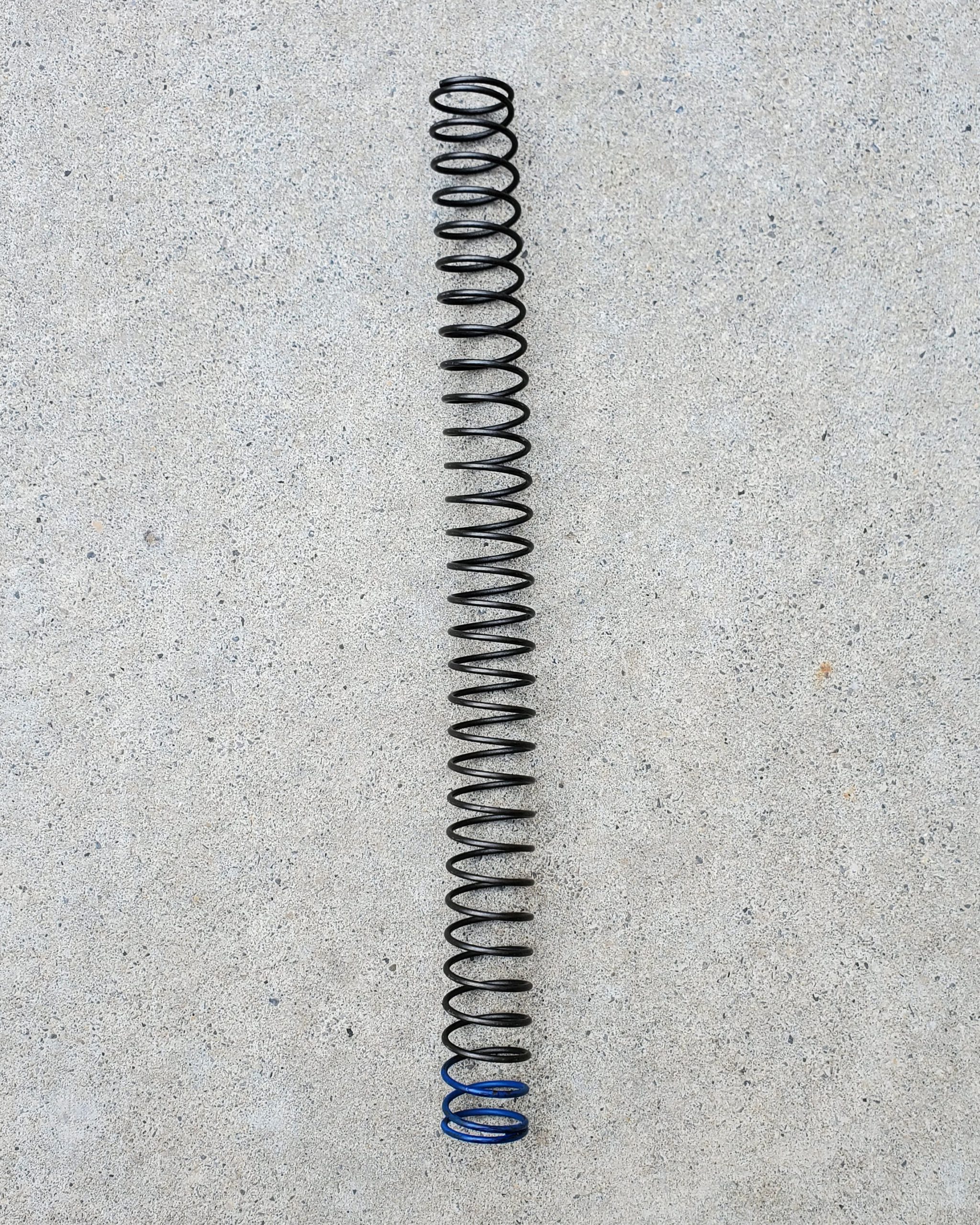

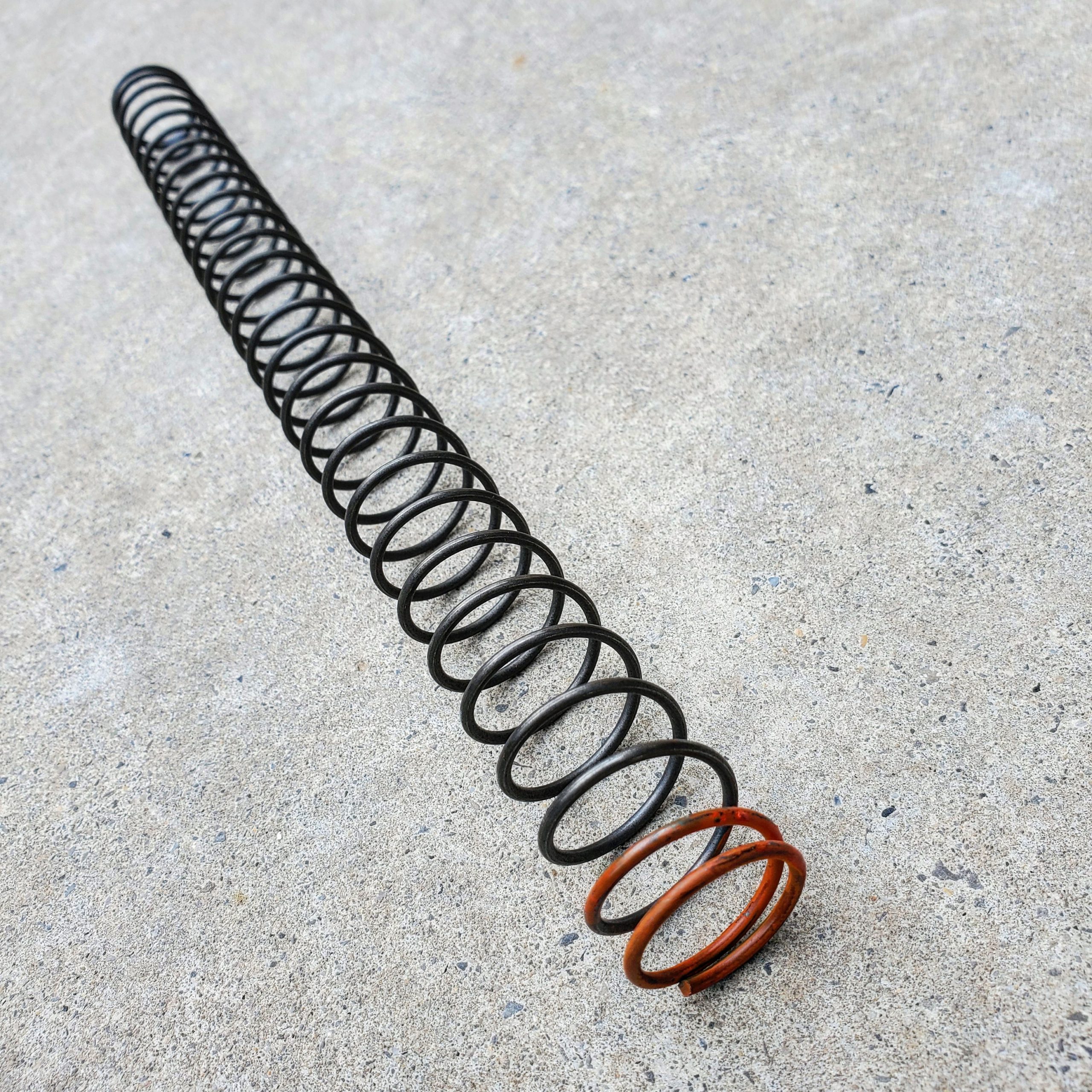

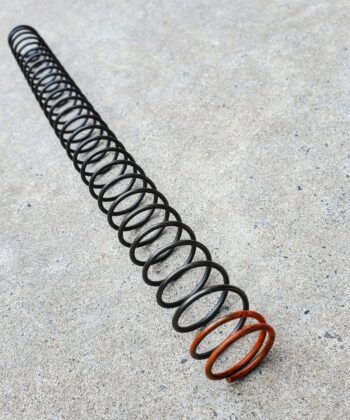

CONSTRUCTION SPECS: CARBINE & RIFLE BUFFER SPRINGS:

- ASTM Grade A877 Certified Valve Quality Chrome Silicon Wirestock

- Heat Treated, Stress Relieved and Dual Stage Shot-Peened post winding (Our springs really ARE shot-peened)

- Impregnation / Plating with Re-Micronized Molybdenum Disulfide formulation

- Hard plastic tube packaging for protected transport and easy storage

- Optional Cryogenic Processing available upon request

ADVANTAGES:

-

Improved & consistent cyclic operation. Spring will not change performance for many hundreds of thousands of rounds.Greater resistance to heat induced performance degradationReduced cyclic rate with Enhanced or Extra Power springs and reduce / eliminate bolt bounce with optimal spring / buffer weight selection.Reduced operating cost as replacement springs are not needed during the life of your upper receiver assembly. Less downtime and fewer trips to the armorer for spring replacement, in fact, this will most likely be the only buffer spring you will ever need for the duty cycle of your carbine or rifle!Correct spring selection works reliably, consistently, and virtually indefinitely in all properly built and maintained AR platforms.

BUFFER (ACTION) SPRINGS

THE MOST COMPREHENSIVE SOLUTIONS IN THE INDUSTRY FOR OPTIMIZING THE PERFORMANCE OF YOUR BLACK RIFLE/CARBINE

** Please NOTE** Due to the inconsistency & minimal power factors used with low power SRTA training or SIMS Rounds, use the Reduced Power (YELLOW) Spring for these training operations.

| Weight | N/A |

|---|---|

| Dimensions | N/A |

| Spring Color | Green, Blue, Red, Orange, White, White Hot, Yellow |

Be the first to review “Sprinco Action Spring” Cancel reply

Related products

AR-15 Parts

AR-15 Parts

AR-15 Parts

Reviews

There are no reviews yet.